The United Arab Emirates (UAE) has rapidly emerged as a global hub for various industries, including manufacturing, technology, and construction. Among the sectors experiencing significant growth is metal enclosure manufacturing. This blog explores the factors contributing to the rise of metal enclosure manufacturers in the UAE, their key offerings, and the implications for industries reliant on high-quality metal enclosures.

Understanding Metal Enclosures

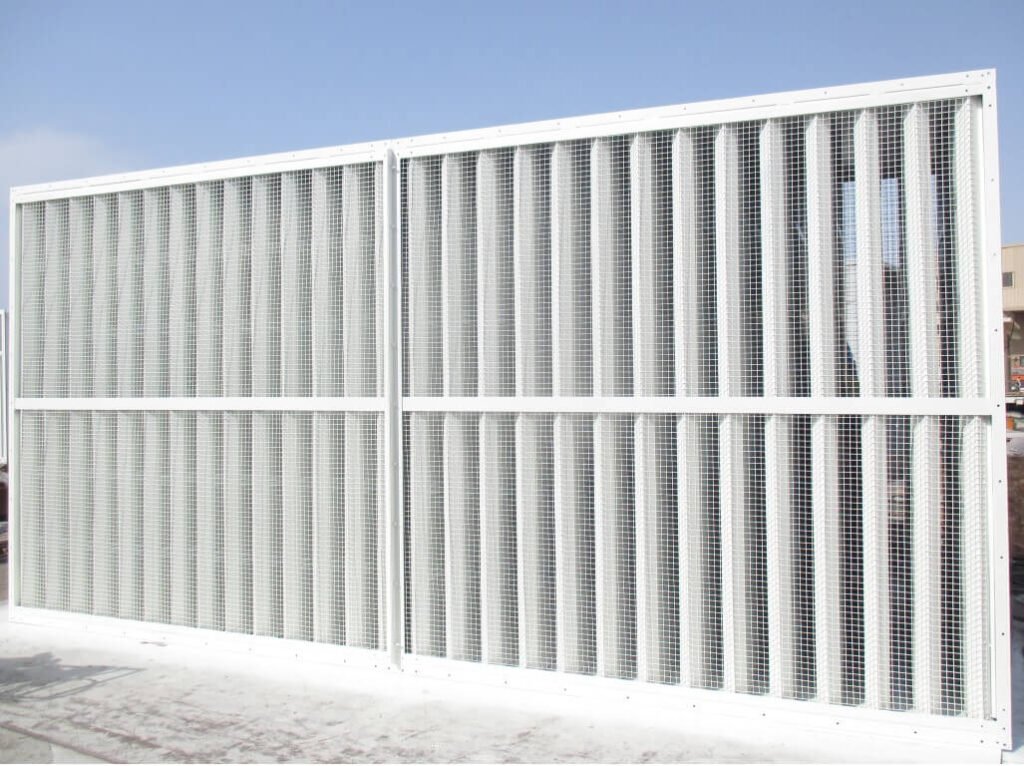

Metal enclosures are protective casings made from metals such as steel, aluminium, or stainless steel. They serve various purposes, including protecting electronic equipment, housing electrical components, and safeguarding sensitive instruments from environmental elements. In an increasingly digital and interconnected world, the demand for durable and reliable enclosures is surging, driven by sectors like telecommunications, industrial automation, and renewable energy.

Factors Driving Growth

Strategic Location

The UAE’s geographical location at the crossroads of Europe, Asia, and Africa provides manufacturers with easy access to emerging markets. This strategic positioning enables metal enclosure manufacturers to serve not only the local market but also export their products to neighbouring regions, enhancing their competitive advantage.

Diversification Initiatives

In recent years, the UAE government has focused on diversifying the economy away from oil dependency. Initiatives such as the UAE Vision 2021 and the Abu Dhabi Economic Vision 2030 aim to promote industrial development and technological innovation. Metal enclosure manufacturing aligns perfectly with these goals, contributing to the growth of a robust manufacturing sector.

Increasing Industrialization

The UAE is witnessing rapid industrialization, particularly in sectors such as construction, oil and gas, and renewable energy. As these industries expand, the need for reliable metal enclosures to protect critical equipment and infrastructure grows. Manufacturers are responding to this demand by producing a variety of enclosures tailored to specific industry needs.

Technological Advancements

Innovation in manufacturing processes has significantly improved the production of metal enclosures. Techniques such as laser cutting, CNC machining, and automated welding have enhanced precision and efficiency. Metal enclosure manufacturers in the UAE are leveraging these advancements to produce high-quality products that meet international standards.

Key Offerings of Metal Enclosure Manufacturers

Customization

One of the standout features of metal enclosure manufacturers in the UAE is their ability to provide customized solutions. Businesses often require enclosures that fit specific dimensions, materials, and functionalities. Manufacturers in the UAE are adept at collaborating with clients to design enclosures that meet their unique specifications, ensuring optimal protection and functionality.

Diverse Product Range

From small junction boxes to large cabinets, metal enclosure manufacturers in the UAE offer a diverse range of products. This includes:

- Electrical Enclosures: Protecting electrical components from dust, moisture, and mechanical damage.

- Control Panels: Used in industrial applications to house controls and instruments.

- Server Racks: Essential for data centers and IT infrastructure.

- Outdoor Enclosures: Designed to withstand harsh environmental conditions.

Quality Assurance

Quality is paramount in the manufacturing of metal enclosures. UAE manufacturers adhere to strict quality control measures, often complying with international standards such as ISO 9001. This commitment to quality ensures that the products are durable, reliable, and capable of withstanding the rigours of various applications.

Applications Across Industries

The versatility of metal enclosures makes them applicable in numerous sectors:

- Telecommunications: Protecting equipment from environmental factors to ensure uninterrupted communication services.

- Oil and Gas: Safeguarding sensitive instruments and controls in harsh and hazardous environments.

- Renewable Energy: Housing solar inverters and other components to ensure their efficiency and longevity.

- Transportation: Providing secure storage for electronic systems in vehicles and aircraft.

The Future of Metal Enclosure Manufacturing in the UAE

As the UAE continues to invest in infrastructure and technological innovation, the metal enclosure manufacturing sector is poised for further growth. Key trends likely to shape the future include:

Sustainability

With a growing emphasis on sustainability, manufacturers are increasingly focusing on eco-friendly materials and processes. The adoption of recyclable materials and energy-efficient production techniques will not only reduce environmental impact but also appeal to a market that values sustainability.

Smart Enclosures

The integration of smart technology into metal enclosures is on the horizon. This includes features like temperature monitoring, remote access, and IoT capabilities, allowing for enhanced performance and monitoring of critical systems.

Export Opportunities

As UAE manufacturers continue to enhance their capabilities, there are ample opportunities for exporting products to emerging markets in Africa, Asia, and beyond. This expansion can lead to increased revenue and the establishment of the UAE as a key player in the global metal enclosure market.

Conclusion

The metal enclosure manufacturing sector in the UAE is thriving, driven by strategic advantages, industrial growth, and a commitment to quality and innovation. As industries continue to evolve and require more advanced solutions, metal enclosure manufacturers in the UAE are well-positioned to meet these demands. With a focus on customization, sustainability, and technological advancements, the future looks promising for this dynamic sector. As businesses seek reliable partners to safeguard their critical assets, UAE manufacturers are stepping up to the challenge, cementing their role as leaders in the metal enclosure landscape.